In order to define proper material behavior johnson holmquist ceramics material model for b 4 c and plastic kinematic material model for al6061 t6 4340 steel and epoxy resin was used.

Johnson holmquist ceramics.

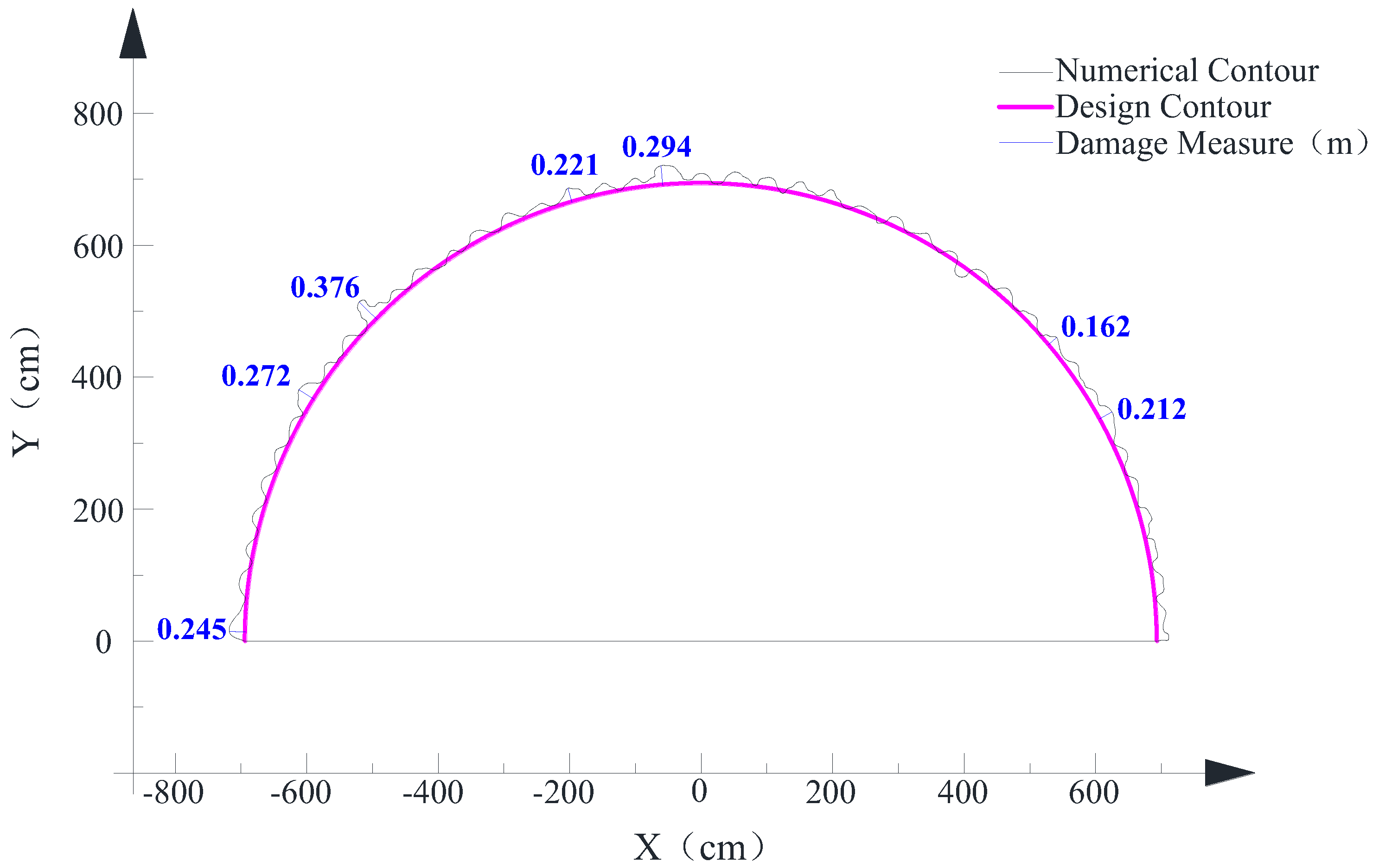

The compression tests simulated for verification of determined jh 2 constants and finally validated by conducting the eoi simulations on glass plates to the spherical and cylindrical shaped projectile.

In recent years johnson holmquist and their coworkers have developed a series of constitutive relations to simulate the response of ceramic materials under large strain high strain rate and high pressure impacting conditions.

The johnson holmquist material model jh 2 with damage is useful when modeling brittle materials such as ceramics subjected to large pressures shear strain and high strain rates.

The constitutive behaviour of alumina ceramics at high strain rates was quantified using the johnson holmquist material model with damage jh 2 a widely accepted model for brittle materials subjected to high loading rates high pressure and large deformation.

Implementation and validation of the johnson holmquist ceramic material model in ls dyna inproceedings cronin2003implementationav title implementation and validation of the johnson holmquist ceramic material model in ls dyna author d.

The johnson holmquist model for simulating impact and penetration into ceramic and glass materials is commonly used in continuum hydrocodes.

The johnson holmquist model commonly used for cera mic materials was enhanced by riedel and co workers 30 31 leading to the rht model.

By incorporating the compression and tensile test data johnson holmquist ceramic jh 2 model parameters were estimated for aluminosilicate glass.

Ceramic materials are commonly used in armor protection applications.

The armor structures were subjected to 7 62 mm ogive nosed steel projectile impact.

The johnson holmquist ceramic constitutive model was first proposed to describe the response of brittle materials to large deformations.